Designers and manufacturers of Torque Limiters since 1977

Howdon Power Transmission are a specialist engineering firm with clients all over the world. They have been involved in the design and manufacture of torque limiters for over 40 years.

They invented the revolutionary Wedgegard® Shearpin Torque Limiter in 1977 to address demand for a simple solution to torque overload protection. A torque limiter is a device that protects mechanical equipment, such as conveyors and pumps, from damage by jamming or overload.

Rotech Systems are proud to join forces with Howdon, to aid in the sales and distribution of these exceptional products worldwide.

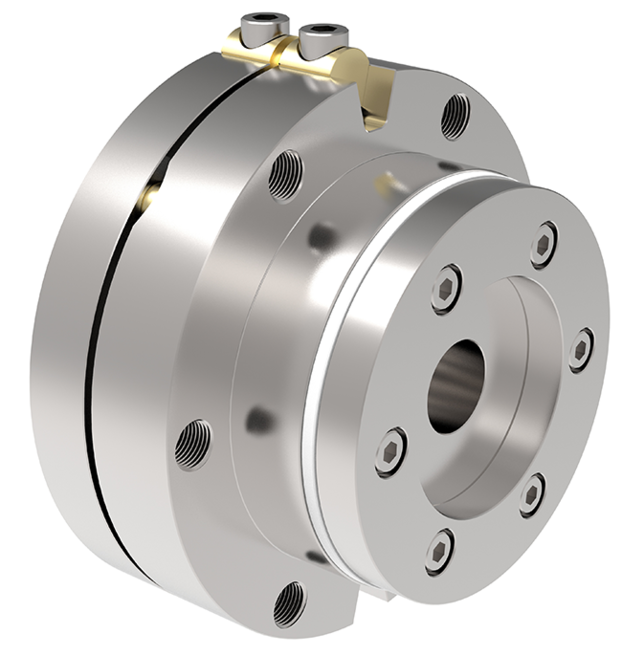

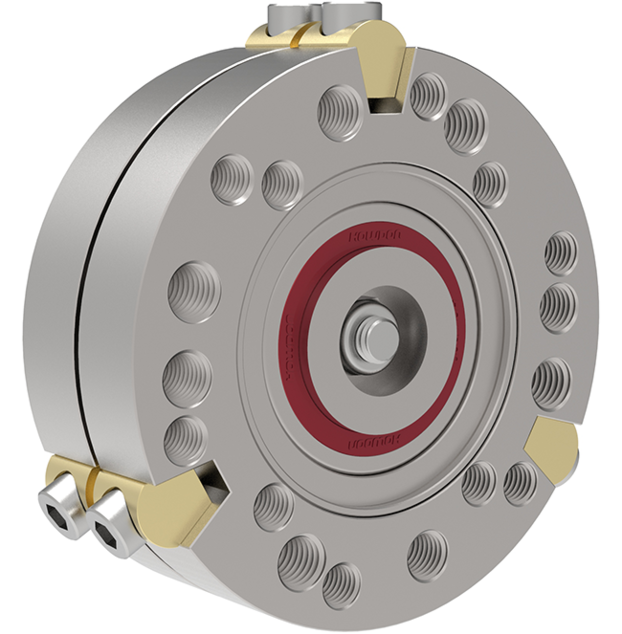

Gear Coupling Spacers

- Gear Type Wedge guard Coupling Spacers can be supplied, bored and keyed to customer requirements.

- All Couplings manufactured to AGMA standards.

- Standard Units for release torques up to 286,800 Nm. Torque is adjustable by Wedge-pin ratings.

- Designs to suit special drive requirements are available. Maximum Speed 500 RPM.

- For speeds greater than 500 RPM units should be balanced.

Type SAE Spacer

Universal Joint Shaft Couplings

- Fits standard SAE UJ (Universal Joint) companion flanges. Release torque is adjustable by Wedge pin ratings.

- The maximum release torque is based on maximum Wedge pin capacity and not UJ shaft capacity – Check your UJ shaft manufacturers max load rating.

- Spigot diameters may change on higher rated UJ shafts.

- When selecting high overloads always limit the release torque to 90% of UJ shaft manufacturers full load rating.

Applications include: Aircraft Refuelers, Asphalting Vehicles, Bin Dischargers, Dynamometer Drives, Food Mixers, Gully Emptier, Liquid Fertiliser Sprayers, Mulching Equipment, Nuclear Process Plant, Road Salting Vehicles, Road Tankers, Spray Tunnels, Test Bed Drives, Tube Rolling Mills, Vehicle Cargo Pumps

Type DIN Spacer

Universal Joint Shaft Couplings

- Fits standard DIN UJ (Universal Joint) companion flanges. Release torque is adjustable by Wedgepin ratings.

- The maximum release torque is based on maximum Wedgepin capacity and not UJ shaft capacity- Check your UJ shaft manufacturers max load rating.

- Adaptor Flange maybe required when fitting to PTO Gear Box Flange.

- Spigot diameters may change on higher rated UJ shafts.

- Sizes 150 and above are supplied with face keyways.

- When selecting high overloads always limit the release torque to 90% of UJ shaft manufacturers full load rating.

Application include: Aircraft Refuelers, Asphalting Vehicles, Bin Dischargers, Dynamometer Drives, Food Mixers, Gully Emptier, Liquid Fertilizer Sprayers, Mulching Equipment, Nuclear Process Plant, Road Salting Vehicles, Road Tankers, Spray Tunnels, Test Bed Drives, Tube Rolling Mills, Vehicle Cargo Pumps

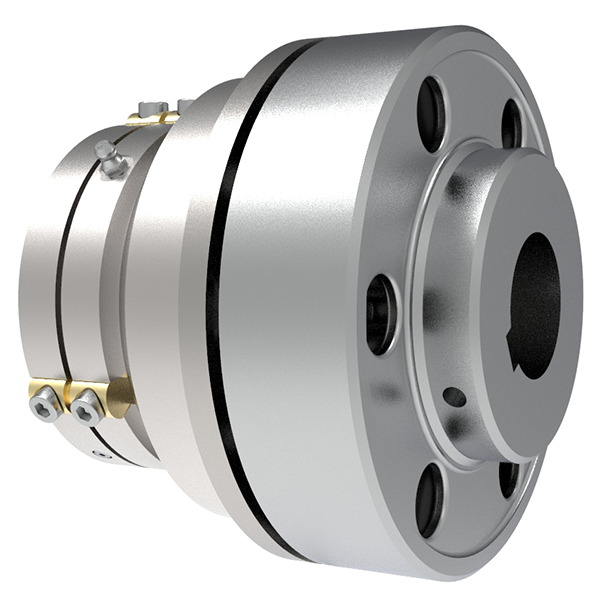

Flexible Couplings

Type CFS Coupling

- Type CFS Wedgegard couplings combine a Centaflex half coupling with the Wedgegard torque limiter.

- Units can be supplied, bored and keywayed to customer requirements.

- Standard Units for release torques up to 64,000 Nm. Torque is adjustable by Wedgepin ratings.

- CFS Couplings are designed for safe operation in a wide range of high torque applications.

- Compensates for axial, radial and angular misalignment, offering heavy duty performance and compact dimensioning.

- Standard finish – Natural.

- For speeds up to 120 RPM.

Applications include: Dredgers, Millers, Loaders, Concrete mixers and pumps, Road finishers, Rail vehicles, Agricultural machines

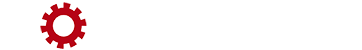

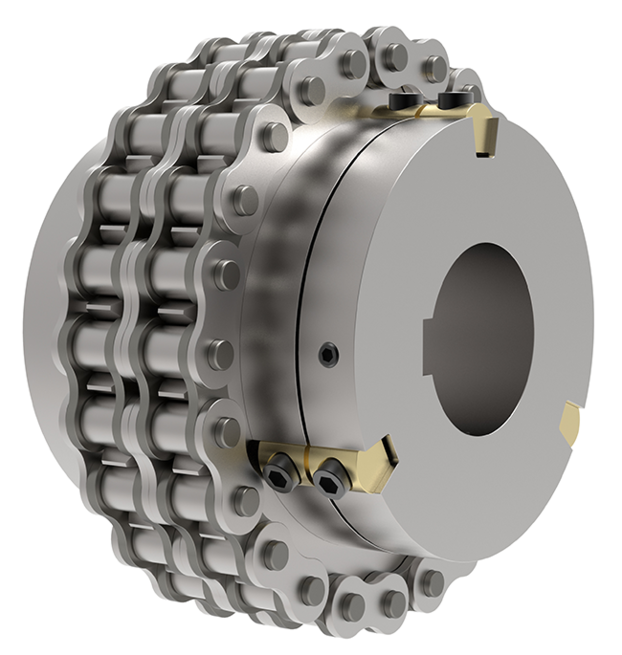

Chain Couplings

- Chain Type Wedgegard Couplings are supplied, bored and keywayed to customer requirements.

- Standard Units for release torques up to 561580 ft-lb.

- Torque is adjustable by Wedgepin ratings.

- Designs to suit special drive requirements are available.

- Standard natural finish on Wedgegard unit and chain coupling, chemical blacking as an option.

- Higher Release/Shear Torques may be available.

- For speeds up to 120 RPM.

Application include: Brick Making Machines, Manipulators, Conveyors

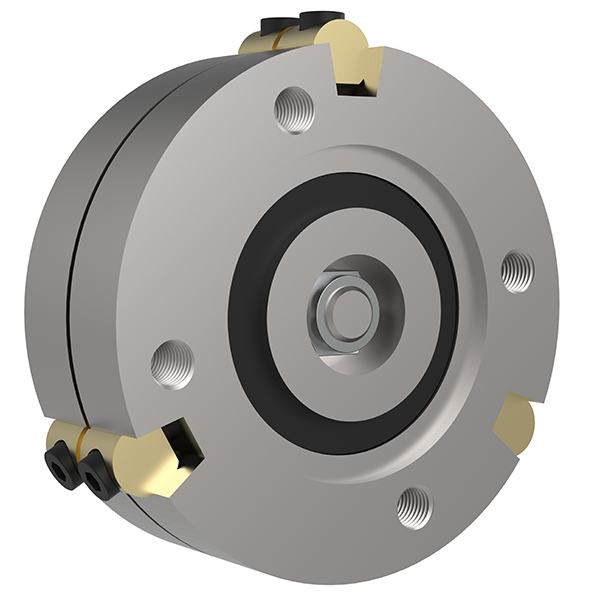

Water Industry Couplings

- Easy access – drive reset in minutes.

- Wedge construction gives maximum rigidity with no backlash. Ideal for indexing or reversing drives.

- Clamping screws give positive axial location. Shear neck cannot be displaced from correct position between flanges.

- Equal load sharing with multiple pins on high torque drives. Very high capacity within compact dimensions.

- Shear necks are standardised and colour coded, giving safe, tamper proof repeatability and spares economy.

- “Fail-safe” under all conditions. Not affected by changes in temperature or humidity. Ability to release not dependent on mechanism lubrication.

The most effective method of protecting rotating machinery from overload is a simple shear-pin. Proved to be reliable for long term protection on slow running / high torque drives, a shear-pin gives full strength directly as a frictionless drive load.